A Guide to Kai Shun Blade Steel Types

Steel is an alloy of iron and carbon; the atoms of one element occupy the spaces between the atoms of the other so that the materials are inextricably joined. Most steel also has ingredients to enhance specific characteristics. For example, stainless steels contain chromium to enhance stain resistance.

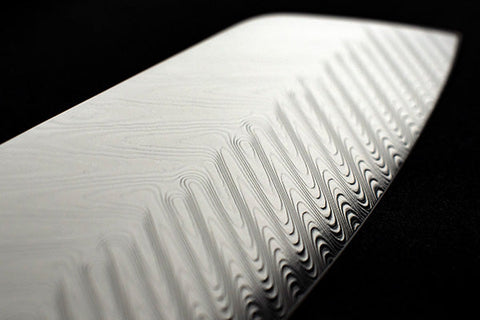

Every Kai Shun knife begins with exceptional steel — the foundation of its sharpness, precision, and enduring beauty. Our blades are crafted from premium Japanese steels chosen for their balance of performance, corrosion resistance, and edge retention. Below is an overview of the steels featured across our Kai Shun collections in New Zealand.

VG10

Used in: Shun Sora Series

A sophisticated steel alloy that combines iron and carbon with chromium, manganese, molybdenum, silicon, and vanadium. Each element plays a crucial role in enhancing blade performance, improving wear resistance, corrosion resistance, hardness, and toughness. Vanadium is particularly important as it refines the steel's grain structure, enabling Shun's signature razor-sharp edge that maintains its cutting ability over extended use.

VG-MAX

Used in: Shun Classic & Shun Premier Series

The latest evolution in VG super steel technology, VG-MAX is exclusive to Kai Shun. Building upon the proven VG10 formula, this advanced steel has been enhanced with optimised levels of key elements to deliver maximum performance. Higher carbon content provides superior strength and durability, while additional chromium ensures exceptional wear and corrosion resistance. Increased tungsten creates an ultra-fine grain structure, allowing for an extraordinarily sharp edge. Molybdenum further enhances both corrosion resistance and overall strength, and vanadium improves impact resistance while forming vanadium carbides that maintain superior cutting performance over time.

Dual Core VG10 / VG2

Used in: Shun Kagerou

The Dual Core construction features alternating layers of VG10 and VG2 stainless steels, meticulously forged together so both steels form the cutting edge. VG2 is a fine grained, high-carbon, high-chromium Japanese stainless steel that takes and holds a very sharp edge. VG 10 is a sophisticated steel alloy that combines iron and carbon with chromium, manganese, molybdenum, silicon, and vanadium. Each element plays a crucial role in enhancing blade performance, improving wear resistance, corrosion resistance, hardness, and toughness.

VG XEOS

Used in: Seki Magoroku Kaname

This high-hardness stainless steel blade is an enhanced development of VG-MAX steel. It facilitates the creation of an even thinner cutting edge, which reduces cutting resistance and maintains sharpness for longer. Despite being produced without cobalt, VG XEOS achieves the same high hardness and corrosion resistance as VG-MAX. It thus offers outstanding cutting performance and high abrasion resistance.

AUS8A

Used in: Seki Magoroku Benifuji

A Japanese high-carbon, low-chromium (for enhanced sharpness) stainless steel that has proven to provide an excellent balance between toughness and strength, edge holding and corrosion resistance. It is an excellent choice for anyone looking for a knife with versatile properties.

AUS10A

A Japanese high-carbon stainless steel with high strength. This gives it a very sharp cutting capability. Additional elements lend the steel greater elasticity and toughness, improving its corrosion and wear resistance. This makes A(US)10 knives less prone to rust and require less frequent resharpening.